Inquiry into the Way Forward for Apprenticeships

Committee: Employment and Learning

Session: 2008/2009

Date: 17 June 2009

Reference: NIA 42/08/09R

ISBN: 978-0-339-60280-9

DEL Response to the Committee Report on the Inquiry into the Way Forward for Apprenticeships

Session 2008/2009

Second Report

COMMITTEE FOR EMPLOYMENT AND LEARNING

Inquiry into the Way Forward

for Apprenticeships

Together with the Minutes of Proceedings of the committee

relating to the report and the minutes of evidence Ordered by the Committee for Employment and Learning to be printed 17 June 2009

Report: 42/08/09R (Committee for Employment and Learning)

This document is available in a range of alternative formats.

For more information please contact the

Northern Ireland Assembly, Printed Paper Office,

Parliament Buildings, Stormont, Belfast, BT4 3XX

Tel: 028 9052 1078

Membership and Powers

The Committee for Employment and Learning is a Statutory Departmental Committee of the Northern Ireland Assembly established in accordance with paragraphs 8 and 9 of Strand One of the Belfast Agreement and under Standing Order 46 of the Northern Ireland Assembly. The Committee has a scrutiny, policy development and consultation role with respect to the Department for Employment and Learning and has a role in the initiation of legislation.

The Committee has power to:

- consider and advise on Departmental budgets and annual plans in the context of the overall budget allocation;

- approve relevant secondary legislation and take the Committee stage of relevant primary legislation;

- call for persons and papers;

- initiate inquiries and make reports; and

- consider and advise on matters brought to the Committee by the Minister for Employment and Learning.

The Committee is appointed at the start of every Assembly, and has power to send for persons and papers and records that are relevant to its inquiries.

The Committee has 11 members, including a Chairperson and Deputy Chairperson, and a quorum of 5. The membership of the Committee since 9 May 2007 has been as follows:

Ms Sue Ramsey (Chairperson)

Mr Robin Newton * (Deputy Chairperson)

Mr Alex Attwood

Mr Paul Butler

Rev Dr Robert Coulter **

Mr Alex Easton ***

Mr David Hilditch ***

Mr William Irwin ***

Ms Anna Lo Mr David McClarty

Mrs Claire McGill

Mr Alastair Ross replaced Mr Jim Wells on 29 May 2007

* Mr Robin Newton replaced Mr Jimmy Spratt as Deputy Chairperson on 10th June 2008

** Rev Dr Robert Coulter replaced Mr Basil McCrea on 15 September 2008

*** Mr Alex Easton, Mr David Hilditch and Mr William Irwin replaced Mr Nelson McCausland,

Mr Alastair Ross and Mr Jimmy Spratt on 15 September 2008

Table of Contents

List of abbreviations used in the report

Report

Key Conclusions and Recommendations

Appendix 1:

Minutes of Proceedings relating to the report

Appendix 2:

Appendix 3:

Written Evidence Submitted by Witnesses

Appendix 4:

Appendix 5:

Appendix 6:

List of Abbreviations

used in the Report

‘The Committee’ Committee for Employment and Learning

‘The Department’ Department for Employment and Learning

‘The Executive’ Northern Ireland Executive

‘The Minister’ Minister for Employment and Learning

‘ANIC’ Association of Northern Ireland Colleges

‘ASSC’ Association of Sector Skills Councils

‘ATAs’ Apprenticeship Training Agencies

‘BMC’ Belfast Metropolitan College

‘CAD’ Computer Aided Design

‘CAFRE’ College of Agriculture, Food and Rural Enterprise

‘CBI’ Confederation of British Industry

‘CIFNI’ Construction Industry Forum for Northern Ireland

‘CITB’ Construction Industry Training Board

‘DBIS’ Department for Business, Innovation and Skills

‘DE’ Department of Education

‘DEL’ Department for Employment and Learning

‘DFP’ Department of Finance and Personnel

‘DIUS’ Department for Innovation, Universities and Skills

‘EMA’ Educational Maintenance Allowance

‘ESB’ Employment Services Board

‘ETC’ Engineering Training Council

‘ETI’ Education Training Inspectorate

‘FE’ Further Education

‘FOSEC’ Foyle School and Employer Connections

‘FSB’ Federation of Small Businesses

‘GTA’ Group Training Association

‘ICT’ Information and Computer Technologies

‘ILT’ Information and Learning Technologies

‘ISNI’ Investment Strategy of Northern Ireland

‘NAS’ Role of the National Apprenticeship Service

‘NEET’ Not currently in employment, education or training

‘NICS’ Northern Ireland Civil Service

‘NIE’ Northern Ireland Electricity

‘NI Water’ Northern Ireland Water

‘NOS’ National Operational Standards

‘NVQ’ National Vocational Qualification

‘QCF’ Qualifications Credit Framework

‘QPANI’ Quarry Products Association Northern Ireland

‘SSC’ Sector Skills Council

‘SEMTA’ Sector Skills Council for Science, Engineering and Manufacturing Technologies

‘SME’ Small and Medium Enterprises

‘STEM’ Science, Technology, Engineering and Mathematics

‘WDF’ Workforce Development Forum

Executive Summary

At its meeting of 19th November 2008, the Committee for Employment and Learning (‘the Committee’) agreed to investigate how apprenticeship programmes need to evolve to be responsive to the skills requirements of the modern global economy and how they might be designed to better weather an economic downturn. The stimulus for this Inquiry was the Minister for Employment and Learning’s (‘the Minister’) statement to the Assembly on Tuesday 11th November 2008 with regard to contingencies he is seeking to put in place to help apprentices that have been made redundant in the recession. The Committee is specifically looking at how the current system of apprenticeships might evolve to be more robust in the face of an economic downturn, or recession, and to be more responsive to the fast-changing requirements for particular skills and skills pools in the global economy. This would seek to take the situation regarding the position of apprentices to a new level, beyond the contingencies. In addition, new contracts for Apprenticeships NI will be awarded in 2010, with preparatory work starting in 2009. Ideally, the work coming from this Inquiry will allow the Committee to partner the Department for Employment and Learning (‘the Department’) in shaping and informing that process.

On 26th May 2009, during the compilation of this report, the Minister announced further contingencies for apprentices, particularly focusing on those on short-time working in the manufacturing engineering sector. The ‘Skillsafe’ scheme that the minister announced is aimed at providing additional funding for training for these apprentices with the aim of boosting their wages and ensuring that they remain seen by their employer as an appreciating asset, rather than a drain on resources.

In judging the way forward for apprenticeships, the Committee asked two key questions: “Why don’t employers take up apprenticeships in greater numbers and why do apprenticeships lack status and profile? How can apprenticeships be better protected in a downturn?" At its core this Inquiry is seeking to get to grips with why so many employers, especially SMEs (Small and Medium Enterprises), which form such a big part of our private sector, do not take on apprentices, and how to make apprentices less vulnerable to redundancy in an economic downturn. All of the stakeholders from whom the Committee heard evidence were obviously supportive of apprenticeships and clearly wanted to see them succeed. It was acknowledged by all those who gave evidence that apprenticeships have an important role to play in providing a broad range of technical, professional and employability skills that employers need. It was also widely accepted that the journey from Jobskills to Apprenticeships NI, via Training for Success, has been challenging but worthwhile, providing great benefits to employers, employees and training providers.

In terms of issues that are holding back the uptake of apprenticeships by both employers and individuals, there was a significant degree of agreement on the factors perpetuating this, such as:

- expense;

- burdensome bureaucracy and excessive administration;

- perceived flaws in the funding mechanism;

- the duplication of auditing and inspection;

- problems surrounding Essential skills provision;

- a ‘one-size-fits-all’ approach; and

- apprentices’ travel costs and wage levels;

In addition, it was apparent that apprenticeships do not enjoy a high degree of status and are often seen as a second choice career pathway when compared with the university route. This perception has hampered the recruitment of the highest calibre of candidate to apprenticeships. In sectors which relate to Science, Technology, Engineering and Mathematics (STEM) it has become increasingly difficult to recruit enough apprentices. These STEM subjects have seen a decline in uptake from schools right through to Further and Higher Education. However, it is the STEM sectors which drive the economy forward and require the highest numbers of ‘replacement’ staff and new staff to drive forward workforce and economic development.

This Report details ways in which these issues can be taken forward, with a number of these provisions having the added benefit of making apprenticeships less exposed to an economic downturn. There are recommendations for better marketing and recruitment of apprenticeships, better ways of funding and providing more structured incentivisation, and alternatives to existing forms of administration, auditing and inspection of apprenticeships.

The Committee considered evidence on a variety of innovations that could provide a useful way forward for apprentices, such as: Centres of Excellence and exemplars of Good Practice; areas of expansion, such as non-traditional apprenticeships, public sector apprenticeships and ‘technician’ apprenticeships; quotas of apprentices within the workforce of employers as a pre-requisite to them being awarded public procurement contracts; apprenticeships being a clearly signposted and open-ended career pathway; the shortening of apprenticeships and the creation of ‘fast-tracking’ where appropriate; greater embedding of transferable skills within apprenticeships and the expansion of multi-skill apprenticeships; broadening participation and widening access, with particular reference to all-age apprenticeships and the participation of existing and part-time staff in upskilling and reskilling; the benefits, particularly for SMEs, of Group Training Associations (GTAs) and Apprenticeship Training Agencies (ATAs). The Committee viewed a number of these ideas specifically in the context of whether they would encourage greater SME participation in apprenticeships. The Committee also believes that the construction industry would benefit greatly from the application of GTAs and a Centre of Excellence to give greater consistency of training across the sector. The Committee examined the structure and position of the pre-apprenticeship programmes and how these might be used to allow a ‘safe haven’ in times of economic turbulence for apprentices who have been made redundant.

Finally, the Committee considered the respective roles of the colleges and the employers and employer groups in the provision of apprenticeships. Weighing up the evidence gathered throughout the Inquiry, the Committee made the overarching recommendation that the future of apprenticeships lies in the hands of employers and employer groups. They should be the drivers of how apprenticeships should evolve. In this way the issues that act as a disincentive for employers to take on apprentices can be properly tackled and apprenticeships can be seen as an essential part of every business, large or small. In this way too, the poor image of apprenticeships should also be improved as it will be in the direct interest of the employers and their groups to encourage the best candidates to enter apprenticeships. This is also likely to discourage employers from seeing apprenticeships as a boom time ‘luxury’ and more as an ongoing investment in productivity and profitability. The colleges will maintain the role in which they excel - the provision of directed training and certification.

The Committee offers its recommendations from this Inquiry to the Department for consideration and looks forward to further discussion and agreement in laying the foundations for Apprenticeships NI for 2010.

Key Recommendations

1. The Committee strongly recommends that the Department seeks to make Apprenticeships NI for 2010 employer-focused and configures the contracting process to make this possible, including measures that give employers or employer bodies more responsibility for recruitment and the running of apprenticeships, and those which will encourage the involvement of SMEs. The Committee commends the work that the colleges have done in responding to the needs of employers and their primary focus should remain in the area at which they excel - the provision of directed training and certification.

2. The Committee strongly recommends that the Department engages with employers with respect to the introduction and enforcement of a minimum wage for apprentices and reviews the funding structure within Apprenticeships NI to examine:

- the options for greater funding at the start of apprenticeship programmes and for incentivising during programmes, particularly the move from National Vocational Qualification (NVQ) Level 2 to Level 3 when employers are likely to have higher costs;

- differential funding for apprenticeships where the training requires a higher level of specialisation and is therefore more costly; and

- targeting the support of apprenticeships where the skills will add value to the economy, as the Committee realises that resources are not unlimited.

3. The Committee strongly recommends that the Department engages with colleges and employers to broker more flexible arrangements for the delivery of the colleges’ elements of apprentices’ training, with particular regard to timing, location, cost and the structure of the training – part of this must be a review of the fees structure of Apprenticeships NI.

4. The Committee strongly recommends that the Department examines the feasibility of providing a single point of contact in the Department to deal with the training providers involved in the Apprenticeships NI programme. This single point of contact should have the necessary authority to resolve and action all queries regarding the Department’s input to Apprenticeships NI. All reviews of Apprenticeships NI should be underpinned by the imperative of ensuring that the programme is constantly streamlined and that any unnecessary bureaucracy is identified and eliminated. Streamlining would particularly involve key processes such as administration and inspection. There is a need to ensure that duplication and inefficiency are avoided.

5. The Committee strongly supports any and all efforts by the Department, and other relevant departments, to engage with schools and employers to boost the status and perception of, and recruitment to, apprenticeships. This should include the use of the new Careers Education, Information, Advice and Guidance Strategy in conjunction with the Careers Service to raise the profile of apprenticeships in schools. The Committee would suggest that the importance of this strand of our workforce and economic development makes it worthy of action across the Northern Ireland Executive (‘the Executive’).

6. The Committee urges the Minister to seek the support of his Executive colleagues in establishing in legislation that an appropriate quota of apprentices should be involved in the workforce undertaking any public procurement contract. It is also important to ensure that these apprentices remain employed with the contractor beyond the period of the contract.

Other Recommendations

7. The Committee commends the Minister on the introduction of the ‘Skillsafe’ scheme. The Committee recommends that the Minister considers its expansion into other sectors beyond manufacturing engineering, particularly prioritising areas where skills add value to the economy.

8. The Committee recommends that the Department, through contracting arrangements and engagement with suppliers and employers, makes every effort to ensure that the transition from an NVQ Level 2 to a Level 3 apprenticeship is as seamless as possible, with continuity of provision to the apprentice being the priority. The Committee would also advocate that movement beyond NVQ Level 3 into Further and Higher education should also be as straightforward and fluid as possible.

9. The Committee urges the Department to engage with training suppliers and employers to explore the possibilities for Information and Learning Technologies within apprenticeship programmes and for apprentices’ independent learning and actively supports and encourages the use of these kinds of facilities.

10. The Committee recommends that the Minister searches out examples of former apprentices who have reached management level in companies such as Bombardier, NIE, Phoenix Gas and geographicially representative SMEs. Such individuals must be put at the heart of future advertising campaigns for Apprenticeships NI, illustrating that apprenticeships are an open-ended career pathway. Media formats more readily accessed by young people should be targeted and less traditional apprenticeships should be highlighted.

11. The Committee recommends that the Department undertakes an analysis of the reasons for non-completion of apprenticeships and factors this into the model for Apprenticeships NI.

12. The Committee recommends that the Department continues to engage with the Education and Training Inspectorate (ETI) and the representatives of the construction industry and its employers to identify ways to eliminate some of the structural obstacles that exist within areas of the sector to the provision of broader and better supported training for apprentices. The Committee further recommends that the Centre of Excellence and GTA models are examined for their appropriateness in meeting these sectoral needs.

13. The Committee strongly recommends that the Department examines all the issues and suggestions that have been made by stakeholders with regard to Centres of Excellence, with a view to proceeding towards the establishment of such facilities.

14. The Committee recommends that the Department examines the opportunities for establishing apprenticeships (and pre-apprenticeships, where appropriate) in the health service here as this has been undertaken successfully within the NHS in England, and that the Minister engages with the Education and Local Government sectors via the Executive to examine the opportunities for establishing apprenticeships (and pre-apprenticeships, where appropriate) in these areas.

15. The Committee recommends that the Department engages with the Federation of Small Businesses (FSB), Sector Skills Councils (SSCs) and other stakeholders to examine the options around Group Training Associations (GTAs) providing apprenticeship services to employers.

Introduction

Background

1. During the 2007/2008 session of the Northern Ireland Assembly, the Committee for Employment and Learning (‘the Committee’) undertook an Inquiry into the Department for Employment and Learning’s (‘the Department’) Training for Success programme. One of the key responses to a specific recommendation made by the Committee is that the Department launch apprenticeships as a stand alone brand. The Committee commends the Minister for doing this in September 2008 with the launch of Apprenticeships NI.

2. At its meeting of 19th November 2008, the Committee agreed to investigate how apprenticeships need to evolve to be responsive to the skills requirements of the modern global economy. The investigation resulted from the Minister for Employment and Learning’s (‘the Minister’) statement to the Assembly on Tuesday 11th November with regard to contingencies he is seeking to put in place to help apprentices that have been made redundant in the recession. The Committee took this as an opportunity to undertake, earlier than planned, an Inquiry into Apprenticeships NI, specifically looking at how the current system of apprenticeships might evolve to be more robust in the face of an economic downturn, or recession, and to be more responsive to the fast-changing requirements for particular skills and skills pools in the global economy. This would seek to take the position of apprenticeships to a new level, beyond the contingencies. In addition, new contracts for Apprenticeships NI will be awarded in 2010, with preparatory work starting in 2009. Ideally, the work coming from this Investigation will allow the Committee to partner the Department in shaping and informing that process.

Objective and Terms of Reference

3. The objective of this Investigation is:

“To collate and consider the opinions and views of the providers, recipients and the utilisers of apprenticeships, and to seek useful regional and international examples of good practice in apprenticeships, with a view to producing a report of recommendations to the Minister for Employment and Learning".

4. In meeting this objective, the Committee received briefings from departmental officials and also took evidence from a range of stakeholders. The Committee sought to:

- Establish the expectations and requirements of those undertaking and providing apprenticeships and to relate this to the changing needs of the economy with regard to skills;

- Identify and analyse relevant experience elsewhere in terms of structures, practices and key targets/outcomes; and

- Consider the approach to apprenticeships required by different sectors and determine how this might shape policy interventions and programmes.

5. The Committee hopes that the recommendations flowing from this Investigation will form the basis of a consensus between the Committee and the Minister’s department. From there the Committee hopes that this consensus will inform the evolution of policy on apprenticeships to meet the skills requirements of a modern economy.

The Committee’s Approach

6. A methodology based on evidence gathering (oral and written) was used as the basis for the Committee’s investigation programme. Written and oral evidence was gathered from:

- the Department;

- the Association of Northern Ireland Colleges;

- the Alliance of Sector Skills Councils;

- the Federation of Small Businesses;

- the Confederation of British Industry;

- Bombardier (operators of their own apprenticeship scheme);

- Northern Ireland Electricity (operators of their own apprentice scheme);

- the Education and Training Inspectorate;

- SEMTA and the Engineering Training Council (NI);

- the Construction Industry Training Board;

- individual apprentices; and

- individual small businesses;

7. Submissions received and minutes of evidence are annexed to this report.

Consideration of Evidence

Context

8. As indicated above, the Committee examined apprenticeships at part of its Inquiry into the Training for Success programme, which reported in May 2008. Flowing from the Committee’s specific recommendation in that Report, the Department removed apprenticeships from the Training for Success programme and established Apprenticeships NI in September 2008. As the economic downturn began to bite more noticeably in the last two quarters of 2008, Committee members were made aware by constituents and other stakeholder groups that growing numbers of apprentices were being made redundant by their employers, effectively preventing them from completing their apprenticeships. The most acute situation appeared to the Committee to be in the construction industry, which had the highest number of apprentices being made redundant and also seemed to be one of the hardest hit of any industry by the economic downturn. The Committee was also made aware of growing numbers of redundant apprentices in other industries.

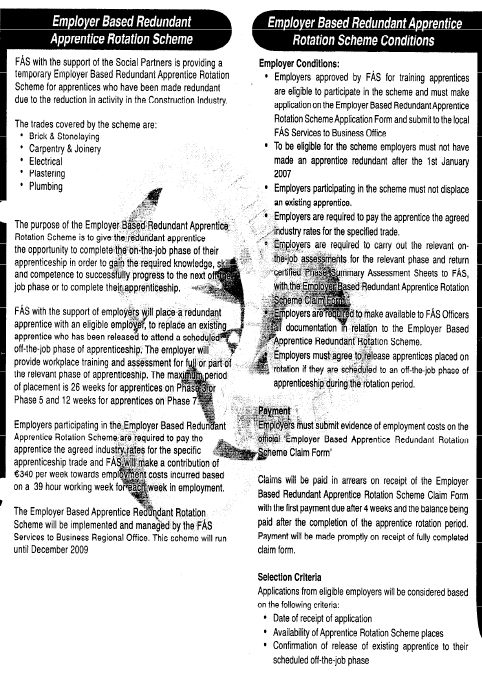

9. The Committee expressed its concern regarding this situation to the Minister and suggested that his Department should investigate how it might provide options for redundant apprentices that might allow them to continue their apprenticeships. In response, the Minister indicated a number of contingency arrangements that his Department would put in place in an effort to address the situation regarding redundant apprentices who were unable to complete their apprenticeship. The Minister made a statement to the Assembly on 11th November 2008, publicly announcing the contingency arrangements for redundant apprentices in the construction, engineering and motor vehicle industries, as follows:

- the Department will engage with the ASSC and other relevant employer bodies, to encourage alternative employers to take on any apprentices who have been made redundant. These ‘Foster Employers’ will include employers with a history of investing in apprentices, as well as employers who perhaps have not done so before. To support this commitment the Department will contribute a small amount of conditional funding towards the additional wage costs;

- for those apprentices who have been made redundant, but are unable to find a Foster Employer, the Department will put in place provisions to permit them to continue training, and work towards the completion of their Apprenticeship Framework;

- for apprentices aged 18 and over within the construction, engineering and motor vehicle sectors, the Department will use the Steps to Work employment initiative to offer NVQ Level 2 or Level 3 placements with employers of up to 52 weeks. This will allow these apprentices to continue their NVQ training and assessment under this programme, whilst separate arrangements will be put in place with Further Education (FE) colleges to offer a Technical Certificate and Essential Skills training - free of charge - through either evening or weekend classes. Whilst on Steps to Work, apprentices will be entitled to a benefit-based training allowance and may also qualify for other benefits; and

- for apprentices who are aged 16 and 17, and have been made redundant, the Pre-Apprenticeship component of Training for Success will allow them to return to training, and complete the Technical Certificate and Essential Skills elements of an Apprenticeship Framework. It is anticipated that this training period will make these participants much more employable, allowing them to complete the NVQ qualification once back in employment.

10. The Minister acknowledged that the success of the contingencies depends on employer placements and conceded that falling numbers of placements had created the redundancies in the first place. He further indicated that, should the contingency arrangements seem no longer appropriate that he will ask his officials to examine other interventions.

11. The Minister also confirmed that the basic tenet of apprenticeships is that apprentices must be in employment to complete their framework and demonstrate competence in the workplace and that the full time training option cannot deliver that.

12. The Committee commends the Minister on his actions in putting in place contingency arrangements for the benefit of redundant apprentices; however, the Committee believes that the arrangements are too heavily dependent on employers being able to take on additional apprentices without sufficient incentives being put in place to facilitate that. The Committee regards the apparent failure of Foster Employers coming forward as an illustration of this. The initiative would therefore seem to have been announced prematurely without sufficient preparation and would appear to reflect poorly on the advice received by the Minister.

13. The Committee’s view that the current format of Apprenticeships NI is not protecting apprentices from redundancy, and the belief that the contingency arrangements above, announced by the Minister, do not go far enough, prompted the Committee at its meeting on 19th November 2008, to agree to look at how Apprenticeships NI can evolve to include better strategies for apprentices in economic downturns and might be more responsive to the needs of employers in our predominantly Small and Medium Enterprise (SME) private sector economy, while also rising to the challenges of an increasingly global economy.

14. During the compilation of this Report the minister put in place further arrangements for apprentices during the recession. On 26th May the Minister announced to the Assembly that his Department will begin the operation of a new ‘Skillsafe’ scheme from 8th June 2009. This scheme will make up to £6M available for training apprentices placed on short-time working. Funding will come partly from the Department’s existing budget and partly from the European Social Fund. The idea is that the apprentice’s employer and the relevant training organisation will, with the Department’s help, fill the apprentice’s ‘down time’ with accredited training that will contribute to their apprenticeship. The apprentice will be paid a training allowance to offset their reduced pay from the short-time working. In addition, the scheme will contribute to the additional training cost involved. The purpose of the scheme, and hence the name, is to preserve the skills that are being developed in apprentices and help to lessen the likelihood that an employer may be forced to move from short-time work for apprentices to redundancy. The programme will initially focus on the manufacturing engineering sector and will potentially expand into other sectors. The Minister indicated that he will announce further interventions in the future.

15. The Committee commends the Minister on the introduction of the ‘Skillsafe’ scheme. The Committee recommends that the Minister considers its expansion into other sectors beyond manufacturing engineering, particularly prioritising areas where skills add value to the economy.

16. The Committee received considerable evidence from stakeholders and Members quickly realised that apprenticeships undertaken in different sectors operate at very different levels and standards. While the Committee accepts that the different nature of varying sectors will mean that they will operate apprenticeships differently, Members were not content that all apprentices were receiving an equal start to their professional career.

Apprenticeships NI

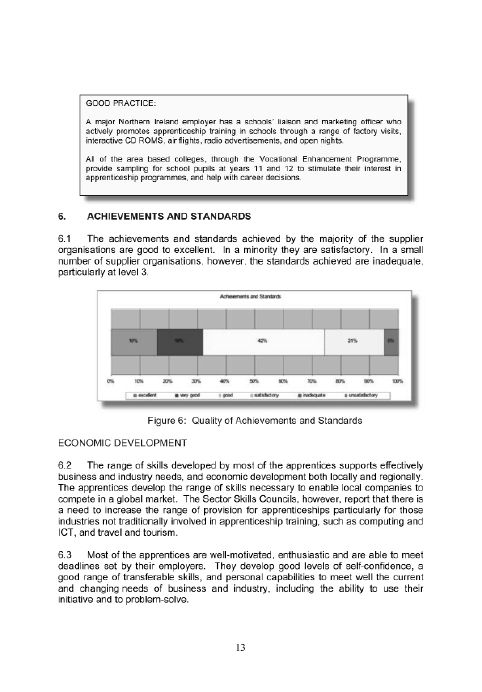

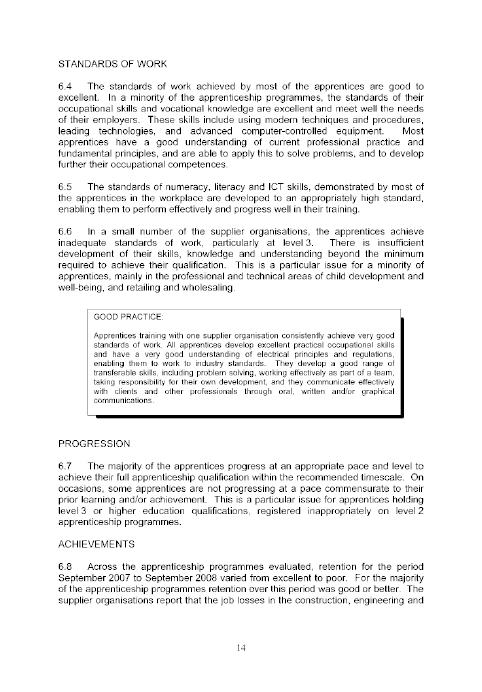

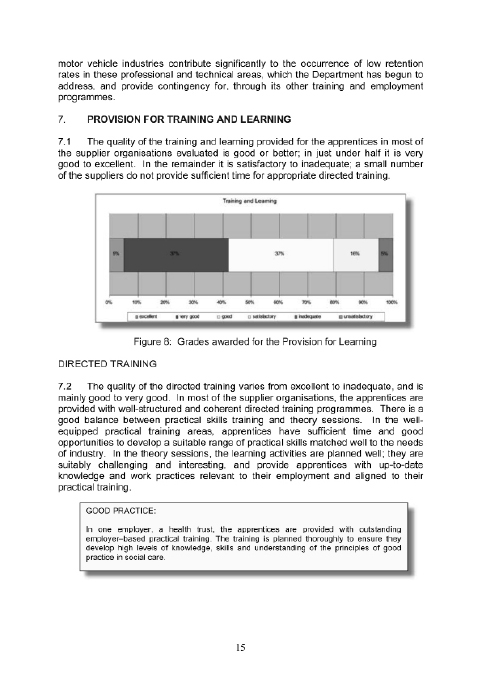

17. The Education and Training Inspectorate (ETI) undertook a survey of Apprenticeships NI between November 2008 and January 2009. The Committee considers it might have been useful if the Executive Summary provided statistics or quantified measurements. The ETI measured the effectiveness of Apprenticeships NI based on how well it meets the needs of the apprentices, the employers and the community at large. The programme was also evaluated on how it meets the broader aims of social cohesion and economic development here. The survey focused on a number of aspects of the programme, including the quality and appropriateness of provision, standards of achievement, leadership and management, and quality of care, support and guidance experienced by apprentices.

18. The breadth of the survey appeared to be sufficient, with 19 training supplier organisations being visited, 26 apprenticeships being surveyed, covering a range of professional and technical areas of a variety of sectors. Over 60 employers were visited for the survey and 246 apprentices were asked to complete a pastoral care questionnaire prior to the survey being carried out. Discussions were also held with representatives of 3 of the Workforce Development Forums (WDF), 12 of the SSCs and the Department. Additionally members of the inspection team visited the Department for Innovation, Universities and Skills (DIUS) and an FE college and the Learning and Skills Council in England to compare and benchmark practice. Again, the Committee cannot see any significant fault in the ETI’s methodology.

Findings

19. The ETI concluded that the quality of training provided by the supplier organisations is mostly good or better with their leadership and management being similarly rated. The survey flagged up the worrying trend that recruitment is still lower than required in priority skill areas such as computing and ICT and software engineering. These issues should be a priority for the Department to address. The survey also flagged up that the majority of apprentices hold less than 5 GCSEs above grade C, or the equivalent. On entry to programmes, a significant minority of apprentices do not hold a Level 2 qualification in literacy or numeracy. The issue of increasing the appeal of apprenticeships to better qualified students has been discussed above in Recruitment; however, the ETI’s survey shows that Apprenticeships NI is tending to be the choice for those students with a limited number of options and, as discussed previously, that situation needs to be addressed. The survey indicated that a minority of the supplier organisations, mostly the Regional Colleges, in collaborations with the SSCs and/or the WDFs, have responded well to the particular training needs of employers through the provision of customised apprenticeships that effectively meet requirements both locally and regionally. The Committee is particularly happy to see that the considerable investment that the Department has made in the Regional Colleges has produced some important benefits and in particular instances the colleges are collaborating productively with SSCs and WDFs to the benefit of employers.

20. An area that the survey highlighted that needs to be dealt with as quickly as possible is the inadequate strategic collaboration and planning between most NVQ Level 2 and 3 suppliers and respective employers. To ensure effective progression at this key stage requires continuity and the elimination of any disruption.

21. The Committee recommends that the Department, through contracting arrangements and engagement with suppliers and employers, makes every effort to ensure that the transition from an NVQ Level 2 to a Level 3 apprenticeship is as seamless as possible, with continuity of provision to the apprentice being the priority. The Committee would also advocate that movement beyond NVQ Level 3 into Further and Higher education should also be as straightforward and fluid as possible.

22. The survey indicates that the majority of apprentices are achieving standards of work that are good to excellent and that retention rates and quality of training and learning provided across the apprenticeship programmes are good or better in the main. Again, greater quantification of these conclusions would have been useful for the Committee. The survey did highlight concerns about inadequate planning for the integration and consolidation of apprentices’ literacy and numeracy skills within their professional and technical programmes – this issue is discussed above. Another issue that needs to be addressed is limited use made by supplier organisations of Information and Learning Technologies (ILT) to support the apprentices’ independent learning through virtual learning environments and online resources.

23. The Committee urges the Department to engage with training suppliers and employers to explore the possibilities for Information and Learning Technologies within apprenticeship programmes and for apprentices’ independent learning and actively supports and encourages the use of these kinds of facilities.

24. Reassuringly, the survey found that the majority of apprentices are well cared for and supported, with most enjoying their apprenticeship programme in an environment that is safe and secure. However, the quality of careers education, information, advice and guidance provided for apprentices on progression pathways to higher level training and education programmes is “variable". As discussed above, it is key that apprenticeships are seen as a good career pathway – one that can take the apprentice to the highest levels in their chosen career. Only when this is established will the status of apprenticeships improve. The issue of the career pathway is discussed further below.

Issues raised by stakeholders during evidence sessions

25. A variety of issues regarding Apprenticeships NI were raised during the evidence sessions that the Committee undertook for the Inquiry, however, there were key themes that the Committee found to be common to most, if not all, of the sessions.

Status, Perception and Recruitment

26. All of the stakeholders presenting evidence to the Committee as part of this Inquiry highlighted issues surrounding the status, perception and, as a consequence of these, recruitment to apprenticeships.

27. It was apparent that all stakeholders have a genuine desire to work in partnership with the Department to improve apprenticeships and make them prosper. However, all the stakeholders indicated that the perception of apprenticeships amongst the general public was of schemes that were somehow old-fashioned and best suited to those who were “not academic" and would not be able to gain entry to university. A strong perception still exists that apprenticeships are limited to “the trades", such as plumbing, construction, or electricians. There is a general lack of awareness as to the sectors where apprenticeships are available and what a modern apprenticeship really is. There is also little recognition generally that apprenticeships can be as open-ended a career path as going to university and gaining professional qualifications there. Despite government efforts, highly skilled craftspeople do not receive the recognition and profile in our society that they deserve. In Germany, craftspeople, scientists and engineers share at least equal status with the professions. This misperception of what apprenticeships are and what they can lead to, continues to diminish their status and leads to difficulties recruiting the best students onto apprenticeship schemes. The challenge is to change that perception and begin building up the status of apprenticeships to the point where they are seen as a career pathway that is weighed equally with university study by young people. Not only do apprenticeships need to be marketed more creatively to students and parents, they must be marketed more effectively to employers.

28. Bombardier indicated to the Committee that it has used a variety of methods over time to encourage applications for its apprenticeship programme; however, the use of radio advertising has been particularly successful over the last couple of years and has boosted applications. The result of a higher number of applications for apprenticeships is likely to be an improvement in the quality of those undertaking an apprenticeship. The knock-on effect of this is likely to be an improvement in the status of apprenticeships. 30% of management graded staff at the Bombardier facilities here began their careers as apprentices. These members of staff often go on to play a significant role in the management and development of other companies, both locally and further afield. Greater effort is required to promote apprenticeships as a modern, high quality training route by the Department and Executive generally.

29. The Committee recommends that the Minister searches out examples of former apprentices who have reached management level in companies such as Bombardier, NIE, Phoenix Gas and geographically representative SMEs. Such individuals must be put at the heart of future advertising campaigns for Apprenticeships NI, illustrating that apprenticeships are an open-ended career pathway. Media formats more readily accessed by young people should be targeted and less traditional apprenticeships should be highlighted.

30. The education sector needs to play a bigger role in the promotion of apprenticeships as a worthwhile and exciting career pathway - ideally there should be parity between vocational and academic qualifications. A vital part of this work needs to be undertaken at curriculum level in schools. It is essential that vocational subjects and qualifications are made more appealing for learners and that the routes and range of options open to students before, during and after GCSEs are better publicised. Vocational qualifications need to be presented to all students as a career pathway that is valued and is as valid as the aspiration to go to university. In the longer term the Confederation of British Industry (CBI) and others have stressed that the provision of careers guidance must be improved. The aim must be to ensure that more students are aware of the opportunities surrounding apprenticeships, thus encouraging more employers to offer them. The ETI has flagged up that while the organisations which supply apprenticeships have improved their uptake, they are also reporting that they are finding it increasingly difficult to promote and market apprenticeships within post-primary schools. Those giving evidence to the Committee advocated that there should be much stronger relationships between the Department, employers and schools regarding the promotion of apprenticeships as a primary, first choice career pathway, rather than a second choice for those who have missed out on their goal.

31. The Committee recommended in its Inquiry Report on the Training for Success programme, that the promotion of apprenticeships should be at the centre of the new Careers Education, Information, Advice and Guidance Strategy. The Department has suggested that this is the case. The Strategy was launched earlier this year by the Department and the Department of Education. The Committee will want to see if the Department’s claim regarding apprenticeships is proven through increased applications for apprenticeships from higher quality candidates who might otherwise have been directed towards university. The CBI’s Education and Skills Survey, 2008, indicated that employers are leaving apprenticeship places unfilled because they cannot recruit suitable candidates. The Committee commends the Minister and the Department for their success in obtaining considerable newspaper coverage of award-winning and other apprentices.

32. The aim of 50% of school leavers progressing to university is based on laudable principles. However, as many stakeholders pointed out in their evidence to the Committee, not everyone needs or should have a degree. However, many employers find that those who are attracted to respond to an advertised apprenticeship vacancy are often those who have not done well academically. For example, heavy vehicle engineering is perceived by careers advisers and society generally as heavy work in a dirty, greasy environment. This perception must be changed – technological changes in vehicle design mean that automotive apprentices now need to be highly computer literate to operate the diagnostic tools used in modern engineering. Apprenticeships must be viewed as a high quality training route – one that should be aspired to and not a safety net for low achievers or those not currently in education, employment, or training (NEETs).

33. While the status of apprenticeships remains low and the perception of those applying being less able remains widespread there will be huge difficulties in the recruitment of the most able students and of companies keen to participate in Apprenticeships NI. Recruitment of both these groups is heavily dependent on the success of promoting the brand.

34. The Committee strongly supports any and all efforts by the Department, and other relevant departments, to engage with schools and employers to boost the status and perception of, and recruitment to, apprenticeships. This should include the use of the new Careers Education, Information, Advice and Guidance Strategy in conjunction with the Careers service to raise the profile of apprenticeships in schools. The Committee would suggest that the importance of this strand of our workforce and economic development makes it worthy of action across the Northern Ireland Executive (‘the Executive’).

35. Many stakeholders highlighted the need to demonstrate a strong link between investment in skills to employers and subsequent improvements in productivity and profitability. It would be foolish to imagine that many employers will be motivated solely by altruism to take on apprentices. Only when the link between skills investment and business improvement is embedded in the minds of employers will they regard apprentices as vital to the wellbeing and development of their businesses and, as a consequence, the status of apprenticeships will be greatly enhanced. All material promoting apprenticeships to employers should make clear references to the link between investment in skills and the potential improvements in productivity and profitability that can result. The benefits of taking on apprentice must be made clearer to employers.

36. The ASSC, indicated in its evidence to the Committee that the achievement/completion of an apprenticeship recognises a high level of skill and competence. The ASSC agrees with the Committee that the distinctive branding of Apprenticeships NI gives a successful apprentice enhanced personal esteem and considerable status with their employer, with the wider sector and with their peer group. Thus, it is apparent that the right kind of promotion can make an apprenticeship significantly more desirable. A number of stakeholders suggested that the use of the term ‘vocational’ may be counterproductive in relation to apprenticeships. The Committee was made aware on its study visit to the USA that the term ‘professional and technical’ is increasingly replacing ‘vocational’ there. Here ‘vocational’ is too often associated with being an inferior alternative to academic study. However, ‘professional and technical’ does sound more career-focused and may be a more useful term with regard to improving the status and perception of apprenticeships. It might be helpful if the word ‘vocational’ in the context of being a descriptor of apprenticeships and considers the phrase ‘professional and technical’ training as a more positive alternative.

37. Many stakeholders giving evidence expressed the belief that apprentices value the esteem of “having a real job" and that this is a great motivator. In their evidence to the Committee, Departmental officials highlighted concerns that the recession will put young people off apprenticeships as it will be seen as an easier option to remain in academic education for as long as possible and undertake courses that are “safe". One of the terms of reference of this Inquiry is to examine how apprenticeships might be made more robust in the face of an economic downturn and that issue is dealt with later in this Report.

38. The ASSC indicated that it needs to be easier for employers and employees to find an appropriate apprenticeship and provider. For some sectors geographical coverage in terms of apprenticeship provision is “patchy". This requires a more structured approach to recruitment of apprentices and would benefit SMEs in particular. The ASSC believes that a new code of practice needs to be devised and adhered to in terms of the employer/provider relationship. They believe that there are still too many apprenticeships being recruited by ‘cold calling’ employers and offering “free training". The likely solution to such issues is to have more of an employer-led apprenticeship programme. The Committee will be interested in the outcome of discussions between the ASSC and the Department on the suggested code of practice governing the employer/provider relationship. The Committee commends the Department on funding an Engineering Training Council (ETC) feasibility study regarding a ‘one-stop-shop’ recruitment service to engineering employers across Northern Ireland. Members look forward to hearing the results of the study.

39. SEMTA and the ETC have suggested that, during an economic downturn, employers and individuals need confidence in training programmes if they are to continue investing their time and money. Analysis of the reasons for non-completion and policies put in place to improve achievement levels will raise confidence in the programme and stimulate interest from both companies and young people. Poor completion rates are a particular concern of companies who invest significant sums in this training. Engineering apprenticeships have a traditionally high completion rate, but other sectors are less successful. The organisations believe that addressing this issue will improve the public perception of apprenticeships as a whole. Bombardier has highlighted that, in a recession, assistance is needed to ensure that apprentices are able to complete their training. The company pointed out that in GB redundant apprentices are able to be funded for up to 6 months to remain in full time training.

40. The Committee recommends that the Department undertakes an analysis of the reasons for non-completion of apprenticeships and factors this into the model for Apprenticeships NI.

41. The Committee is aware that Bombardier is a major sponsor of a programme called ‘Engineering Skills for Industry’. The programme was developed in 2003 following the publication of the West Belfast and Greater Shankill Taskforce Reports. The programme is run by a partnership of training organisations and employers and is designed to provide training to prepare unemployed individuals for employment, having obtained relevant skills. This kind of programme and the activities of organisations such as the Employment Services Board (ESB), on which the Committee has previously been briefed, could be used to provide ‘tasters’ of apprenticeships in different sectors and could be used as a pathway to encourage the unemployed to consider apprenticeships.

Funding Levels and Incentivisation

42. The weight of evidence received by the Committee suggests that funding needs to be flexible enough to meet a wide variety of employer driven needs; for example, Northern Ireland Electricity (NIE), which runs its own apprenticeship scheme, believes that it pays approximately £60,000 for each of its apprentices over a three year apprenticeship, i.e. approximately £20,000 per annum, per apprentice. NIE only receives funding of approximately £4,000 per annum from the Department. In the present difficult economic conditions, NIE has suggested that it might be more appropriate for it to receive closer to 50% for its highly specialised apprenticeship training. Indeed, the company has suggested that the Department should provide differentially higher funding for those providing particularly specialist apprenticeship training. The company has also suggested that a shorter apprenticeship might mitigate against the overall level of funding required and this issue is dealt with below.

43. The view is that an apprentice will be largely economically unproductive for the first year of their apprenticeship, imposing a financial burden on the employer without any immediate benefits. It would therefore seem logical that there should be greater financial support for the employer when their apprentice is in their first year, engaged in full-time training, rather than production activities. It was suggested by the Federation of Small Businesses (FSB) that SMEs, which form the vast majority of our private companies, particularly need some type of funding incentive to take on an apprentice. These employers’ resources are often under particular pressure and their ‘buy-in’ to Apprenticeships NI is not only key to the scheme’s success, but to the success of efforts to raise the general level of skills within our economy. It is also likely that higher initial funding will encourage a better training and wage structure for the apprentice within an SME and may increase the likelihood of the apprentice being taken on permanently on completion of the apprenticeship, according to the FSB.

44. The present scheme recognises the completion of the apprenticeship with an end payment to the employer, but many of the costs to the employer are associated with the start of the apprenticeship, as indicated. A number of stakeholders have suggested that higher and better designed ‘front-loading’ of funding might also have the added benefit of making apprenticeships more attractive to potential apprentices and employers alike, possibly increasing uptake of apprenticeships by both groups.

45. Financial incentives at various points throughout an apprenticeship might encourage apprentices and employers to stay together, thus boosting completion rates. It was also made clear that financial incentives to employers would have to be attractive and more than token gestures. NIE has suggested that, as a short-term measure during the Recession, the Department provides employers with 50% of the overall costs of employing an apprentice and that this be paid up front.

46. Currently the Department indicates that its position is that it does not subsidise the cost of an apprentice to an employer. The apprentice agrees their wage with the employer and the Department pays for training and makes a completion payment to the employer. The Department pays money to the contract provider for training and it is up to them to work out any arrangements with the employer. In its evidence to the Committee the Department admitted that currently, during this recession, there is no real incentive for a financially hard-pressed employer to keep on an apprentice. When Members suggested revisions to funding and possible top-up payments to employers when apprentices are moving up levels within their apprenticeship, Departmental officials acknowledged that this might well be an incentive to employers to retain apprentices in these difficult economic times. Members also expressed concern that, while employers in England are required to pay apprentices an agreed minimum wage (currently £95 per week), here there was no such imperative. In the Committee’s Inquiry Report on Training for Success (which incorporated apprenticeships at that time) it was recommended that the Department “…introduces and enforces, via contracting arrangements, a minimum rate of pay for apprentices, similar to the system currently applied in England". The Department indicated that was waiting for a report from the Low Pay Commission before taking any action. The Committee understands that this Report is now complete and would welcome further engagement with the Department on this issue.

47. The Committee recommends that the Department engages with employers with respect to the introduction and enforcement of a minimum wage for apprentices and reviews the funding structure within Apprenticeships NI to examine:

- the options for greater funding at the start of apprenticeship programmes and for incentivising during programmes, particularly the move from National Vocational Qualification (NVQ) Level 2 to Level 3 when employers are likely to have higher costs;

- differential funding for apprenticeships where the training requires a higher level of specialisation and is therefore more costly; and

- targeting the support of apprenticeships where the skills will add value to the economy, as the Committee realises that resources are not unlimited.

Bureaucracy /‘One size fits all’/Flexibility (including Essential Skills and Auditing and Inspection)

48. Many of the stakeholders who gave evidence during the Committee’s Inquiry stressed that their experience of running and managing apprenticeships under the current programme is that it is bureaucratic, that there is a ‘one-size-fits-all’ approach to all sectors and that the scheme lacks fundamental flexibility that would make it considerably more attractive to both employers and apprentices.

49. A number of stakeholders strongly recommended that sectoral considerations from any part of any policy intervention, as a ‘one-size-fits-all’ approach seldom meets the needs of the range of sectors involved in apprenticeships. It was suggested that some sectors are at the start of their exploration and embedding of the apprenticeship programme and therefore must work hard to raise employer awareness of the programme. While gathering evidence during this Inquiry, the Committee became aware that in some sectors apprenticeships are, on the whole, well run and provide the experience that apprentices require. However, in others the Committee has concerns about standards and the level of real training being provided to apprentices. The Committee realises that this difference can often be based on the nature of a particular sector and the time and financial resources at its disposal. This is one of the reasons why it is important for the Department to be very aware of the needs of different sectors regarding apprenticeships. The description by so many of the apprenticeships programme having a ‘one-size-fits-all’ approach would indicate that the Department needs to give greater prominence to sectoral and employer differences in the programme. Flexibility needs to be built into the contracting model to accommodate this.

50. The Committee believes that sectors such as engineering are already in a strong position regarding apprenticeship programmes but, as discussed above, may well need interventions around offsetting the costs of their programmes, finding suitable tutors and mentors and keeping the provider network stable in terms of resources and equipment. The engineering sector has also voiced great concern regarding the rates of new entrants into engineering required to replace those leaving/retiring and to supply the sector with the personnel needed for expansion. The Committee still retains the concerns it voiced in its Report on the Training for Success programme that the construction sector is not offering apprenticeships of the standard seen in some other sectors. The Committee understands that some of this relates to restrictions on craftspeople, who are being paid a ‘piece rate’, being able to spend as much time training apprentices as is the case in sectors where companies can better accommodate ‘non-productive’ time to train apprentices in all aspects of their work and not just those that generate immediate income. The Committee does not seek to suggest that poor or limited training for apprentices is endemic in the construction industry; however, the Committee understands the particular difficulties encountered in this sector which have been further highlighted by the economic downturn. The Committee believes that some level of solution to the difficulties that the construction industry faces in training apprentices might be found in the Centre of Excellence model, where specialised training and ‘live’ work experience can be undertaken, perhaps even a further degree of assessment. The Committee is conscious that this could then ameliorate in some way a lack in breadth of experience gain on the construction site. In the same way, it might be useful to explore the use of Group training Associations (GTAs) to ensure greater support for construction apprentices in gaining the full breadth of training required. There may be some role for the Construction Industry Training Board (CITB) in this regard, as it is already obtaining a levy from members of the sector to provide training. Centres of Excellence and GTAs are discussed more fully below.

51. The Committee recommends that the Department continues to engage with the Education and Training Inspectorate (ETI) and the representatives of the construction industry and its employers to identify ways to eliminate some of the structural obstacles that exist within areas of the sector to the provision of broader and better supported training for apprentices. The Committee further recommends that the Centre of Excellence and GTA models are examined for their appropriateness in meeting these sectoral needs.

52. The Committee also has concerns about some of the sectors covered by Proskills, particularly glass, printing and furniture. The Committee understands that these sectors are struggling to generate enough apprentices for colleges to consider whether class sizes have reached a viable level for directed training within the colleges. It is not in anyone’s interest for these sectors to be squeezed to the point where the skills are lost. The Department should encourage Proskills and the colleges to engage and examine the difficulties that are being faced in these sectors, particularly glass, furniture and printing, and that a model should be put forward to remedy the situation.

53. SEMTA and the ETC sounded one note of caution regarding the flexibility of the apprenticeships programme. With over 100 apprenticeship frameworks already available here, it is possible that too much flexibility in terms of content of programmes could be introduced. Enabling employers to tailor certain elements is essential, but creating different programmes for every employer risks making the programmes too complex and significantly reducing the portability of the apprenticeship for the individual.

Essential Skills

54. The majority of stakeholders giving evidence suggested that there is a need to improve the flexibility of the colleges and links between colleges and employers within Apprenticeships NI. There was a perception that colleges tend to be rigid and inflexible in delivering their training. It was suggested that greater flexibility would be appreciated in relation to hours, locations and the structure of training. The CBI further highlighted an “excessive" dependence on colleges for the provision of Essential Skills, which should be avoided. In addition, the CBI and other stakeholders flagged up the increasing cost of the FE elements of apprenticeship programmes. Proskills highlighted the amount of ‘down time’ that Essential Skills causes for apprentices and their employers and suggested that greater efforts should be made to look for in-house solutions to delivering Essential Skills that may prove to be cheaper and just as effective. This could include greater use of Distance Learning.

55. This need for increased flexibility in the delivery of the Essential Skills element of the apprenticeship framework will be drawn into sharper focus with the arrival of the third Essential Skill, ICT, in September 2009. For those apprentices without an exemption, the current requirement to complete 40 hours of numeracy essential skills and a further 40 hours of literacy is considered by the majority of stakeholders to be a significant drawback to the scheme. Sector Skills Councils have indicated that they would welcome increased flexibility within this requirement to introduce improved initial assessment, allow for more flexibility with the number of hours assessed for delivery, more focus on contextualising learning materials and embedding in the professional and technical element of the apprenticeship. Apprenticeships should be truly professional and technical, focusing on the provision of skills necessary to perform a particular function.

56. The Committee is aware that in the Scottish and Welsh models, the key/essential skills are embedded as part of the apprenticeship framework. This has been shown to reduce non-completions of apprenticeships. Some stakeholders have suggested that essential skills not being sufficiently embedded within programmes here may well be a barrier to some apprentices not successfully completing their framework. The Committee welcomes the Department’s new guidelines for better integration of Essential Skills into apprenticeship programmes and its request for the ETI to revisit the 40 hour rule regarding Essential Skills, which are part of the Department’s response to the recommendations flowing from the Committee’s Report on Training for Success. The Committee would emphasise the need for continuing engagement with the SSCs and employers regarding the success of the new guidelines for the better integration of Essential Skills into apprenticeship programmes and the appropriateness/relevance of the essential skills generally.

57. The Committee recommends that the Department engages with colleges and employers to broker more flexible arrangements for the delivery of the colleges’ elements of apprentices’ training, with particular regard to timing, location, cost and the structure of the training – part of this must be a review of the fees structure of Apprenticeships NI.

Inspection and Auditing

58. This is a complex issue and the Committee stressed in its Report on Training for Success that there should be comprehensive monitoring and inspection in place for the programme. However, a number of stakeholders have indicated in their evidence that the inspection and auditing regime for Apprenticeships NI is complex and duplication occurs. The ASSC indicated that feedback from some employers and provider networks has highlighted a growing concern regarding duplication of inspections and audits being carried out by too wide a variety of organisations. They have suggested reducing the amount of bureaucracy, paperwork, administration and inspection associated with Apprenticeships NI over time would be welcome. It was highlighted that Sector Skills Councils recognise that given the problems with Job Skills, inevitably the introduction of a new scheme like Apprenticeships NI does require an element of review and fine-tuning in the initial stages to ensure consistency and quality of delivery. They would indicate a need to stabilise the operation of Apprenticeships NI and focus on building the brand. The Committee is sympathetic to suggestions by stakeholders that the auditing and inspection regime of Apprenticeships NI is complex and perhaps a level of duplication has arisen. However, the Committee is also aware that auditing is largely governed by Treasury standards and is not necessarily the sole preserve of the Department.

59. NIE has further suggested that the Department provides one point of contact for training organisations. This person would have a broader remit than the Department’s current contract manager in that they would be empowered to resolve and action all queries, across the entire range of departmental processes and financial requirements. NIE has indicated that an example of good practice in this respect is the Department’s Bridge to Employment scheme, which NIE has actively supported. This provides ease of administration for NIE as a training provider and ultimate employer.

60. The Committee strongly recommends that the Department examines the feasibility of providing a single point of contact in the Department to deal with the training providers involved in the Apprenticeships NI programme. This single point of contact should have the necessary authority to resolve and action all queries regarding the Department’s input to Apprenticeships NI. All reviews of Apprenticeships NI should be underpinned by the imperative of ensuring that the programme is constantly streamlined and that any unnecessary bureaucracy is identified and eliminated. Streamlining would particularly involve key processes such as administration and inspection. There is a need to ensure that duplication and inefficiency are avoided.

STEM (Science, Technology, Engineering, Mathematics) subjects

61. There is a universal understanding that STEM subjects are crucial to the development of both our workforce and our economy. The STEM subjects are drivers for a number of skills/careers areas which have been identified as key to the local economy progressing and being able to innovate and compete in the global marketplace.

62. The Committee has grasped the issue of the shortage of students at a variety of levels involved in STEM subjects, and has done considerable work to highlight concerns. This has included events in Parliament Buildings to highlight the issue, supported by the Education Committee and Enterprise, Trade and Investment Committee and considerable lobbying of the Minister and the Education Minister. Currently the Committee is awaiting the publication of the two departments’ (Employment and Learning and Education) STEM review which, it is hoped will provide a coherent strategy that will boost the numbers of those studying STEM subjects. The Committee will study the Review carefully when it is published and then decide a course of action in response, in conjunction with stakeholders and other Assembly Committees.

63. Evidence has shown that many young people have misconceptions about STEM careers, particularly those linked to the manufacturing industries. It would be useful for schools to have access to STEM mentors, or ambassadors, who have come up through the apprenticeship route and, similarly, it would be useful for greater publicity on the wide range of STEM career opportunities available on the successful completion of a STEM-related apprenticeship. This might include real case studies and examples, giving the student an insight not only into the benefits of an apprenticeship, but real experiences to which they can relate regarding STEM subjects.

64. The ASSC has suggested a number of ways of encouraging STEM apprenticeships, including:

- a higher rate of funding for STEM related apprenticeships/qualifications;

- ensuring that careers/guidance staff have good information about the job opportunities in STEM areas and the skills and qualifications required; and

- distinct marketing for STEM apprenticeships, which includes highlighting the earning potential of those with STEM backgrounds, especially qualifications and skills gained through STEM apprenticeships.

65. It is clear that much more must be done at school level to increase the numbers of students in STEM subjects. An increase in such numbers and a clearer understanding of the opportunities offered by STEM careers is likely to help lift recruitment levels of STEM-related apprenticeships. This would be greatly facilitated by more professional and technical modules being offered as part of GCSEs.

66. In many cases studying STEM subjects will lead into engineering disciplines. The Committee heard considerable evidence from stakeholders in the engineering sector. The Committee was generally impressed with the quality of apprenticeships available in the sector. SEMTA/ETC suggested that engineering apprenticeships here are well-regarded by employers for a number of reasons:

- the programmes have been developed in conjunction with employers and are focused on meeting their needs;

- the programmes are flexible in their incorporation of a range of engineering disciplines, while maintaining a core of common engineering understanding;

- the programmes are demanding and rigorous, providing the apprentice with high levels of technical and practical skills;

- the programmes provide clear progression to further study skills which employers and individuals value;

- the programmes combine theory with practice and wider employability skills; and

- the programmes are supported by a network of providers and colleges who are committed to providing a quality experience for the young person and a service to the employer.

67. The general themes would appear to be employer led and focused apprenticeships, with the right level of support from the Department and colleges and other providers. These key themes will be explored further in the sections below.

68. SEMTA/ETC further highlighted that, as far as engineering employers are concerned, the apprenticeship programme provides them with skills key to the future of the sector. According to these engineering bodies, employers expect all successful apprentices to have a solid grounding in engineering principles and be able to apply these in workplace environment, and wider skills relating to employability. For successful apprentices at Level 3, employers’ expectations are even higher – they are looking for high level technical skills and a real understanding of the processes of engineering in their discipline. Successful advanced apprentices often also demonstrate potential in terms of leadership and management. SEMTA/ETC believe that engineering apprentices themselves are often ambitious and focused on achieving rewarding jobs, which utilise their skills. Many are keen to go on to further and higher education and beyond, as well as acquiring professional status and management responsibility in the workplace.

Further Issues for Consideration

Centres of Excellence and good practice

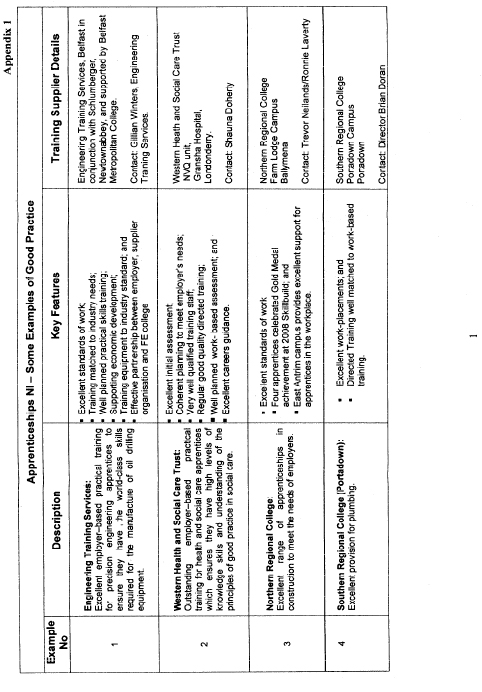

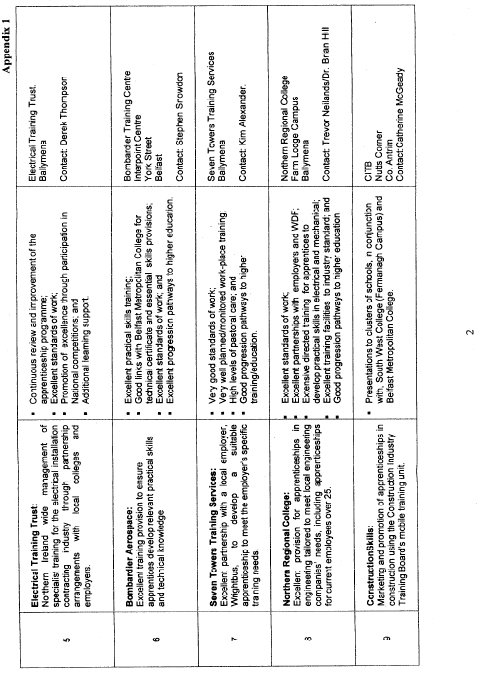

69. The Committee received evidence on the benefits of Centres of Excellence. Some of these were local and some also represent examples of Good Practice.

Bombardier

70. The Bombardier facility in Belfast operates a Centre of Excellence for the design and manufacture of aircraft fuselages, engine nacelle systems, wing components, flight control surfaces and processes, such as advanced composites and computer-aided design (CAD). The company offers a 3 year apprenticeship at this Centre of Excellence, in conjunction with Belfast Metropolitan College (BMC), which leads to an NVQ Level 3. The company has been involved in training apprentices for over 50 years. During the recruitment of apprentices, the company seeks to identify candidates with the necessary skills and abilities and the potential for development. Their knowledge, motivation, perseverance and team-working skills are assessed. Interviews are also undertaken and the candidates are put in rank order. This order dictates which candidates are offered an apprenticeship with the company.

71. Currently, the apprentices are trained in cohorts of around 20 and spend most of their first year at the company’s dedicated training facility at the Interpoint Centre in the heart of Belfast, where they learn foundation skills from 6 specialist trainers. The second and third years of the apprenticeship are more practical and hands-on and incorporate a wide range of operational areas, with a variety of skills being taught and acquired. These experiences generally take place at the company’s five operational facilities. At the end of the first year an internal selection takes place that determines whether apprentices will follow a craft route, leading to City and Guilds qualifications, or a technical route which leads to a Business and Technology Education Council (BTEC) qualification. The NVQ frameworks are developed in conjunction with the ETC and all NVQ qualifications meet SEMTA standards.

72. Retention rates for the company’s apprentice are high and, if everything goes according to plan, apprentices are likely to be employed by the company. As indicated previously, approximately a third of staff at management level in the company have come up through the apprenticeship route and the company is highly supportive of apprenticeship programmes generally. In conjunction with its apprenticeship programme, Bombardier operates an extensive outreach programme where it works closely with schools and young people to highlight the opportunities that are available through an aerospace apprenticeship. This includes interactive workshops, talks to young people by engineers and current apprentices, school competitions and work experience placements for over 200 students each year. The Committee was particularly impressed by the company’s attention to pastoral care for the apprentices and believes that this must be a key part of all apprenticeships programmes.

73. The Bombardier apprenticeship has been reviewed by the ETI and received a “1", being described as “outstanding" and “characterised by excellence". Particular strengths of the programme highlighted by the ETI include:

- the commitment of staff to provide excellent training and learning support;

- the training facilities and resources;

- self-evaluation and improvement planning processes;

- the standards of occupational skills and technical knowledge achieved by almost all apprentices; and

- the retention, success and progression rates of 90%+.

74. The company invests considerable resources in its apprenticeships programme and was one of the stakeholders who suggested more front-loading of funding for apprenticeships, as discussed above.

NIE (Northern Ireland Electricity)

75. The company’s apprenticeships programme, like that of Bombardier, is well established, having been in place for over 30 years. The company highlights that many of the skills required within power transmission and distribution are sector specific and are not easily sourced from other business sectors, industries, or training providers. The company has highlighted that it strongly believes that a targeted and focused apprenticeship is the most appropriate way to develop highly skilled, motivated and committed future employees.

76. The typical NIE apprenticeship lasts 3 years and leads to the completion of NVQs at Levels 2 and 3. The NVQs are supported by 5 full-time NIE accredited trainers and are subject to internal and external verification by City and Guilds. The company boasts an impressive 84% retention rate for its apprentices and those who complete their programme will usually be offered permanent employment by the company. Training takes place in dedicated facilities and at on-site facilities. The company also uses external training providers for specialist areas. Apprentices can also study towards a BTEC National Certificate in Electrical Engineering at an FE college. The company describes its programme as having clear targets and structure. The company, like Bombardier, runs its apprenticeships programme at considerable cost and again, like Bombardier, made the same requests regarding front-loading of funding for apprenticeships.

77. NIE’s memberships of the Energy and Utility Skills SSC and the CBI Employment Affairs Committee allow the company to influence the development of relevant NVQs which are specifically tailored to the power transmission and distribution industry. The company indicates that it also tries to develop ‘softer’ skills through its apprenticeship programmes, such as self-motivation, flexibility, integrity, interpersonal skills, team-working skills, decisiveness and assertiveness. There is also pastoral care support, which the Committee commends.

Fashion Retail Academy (London)